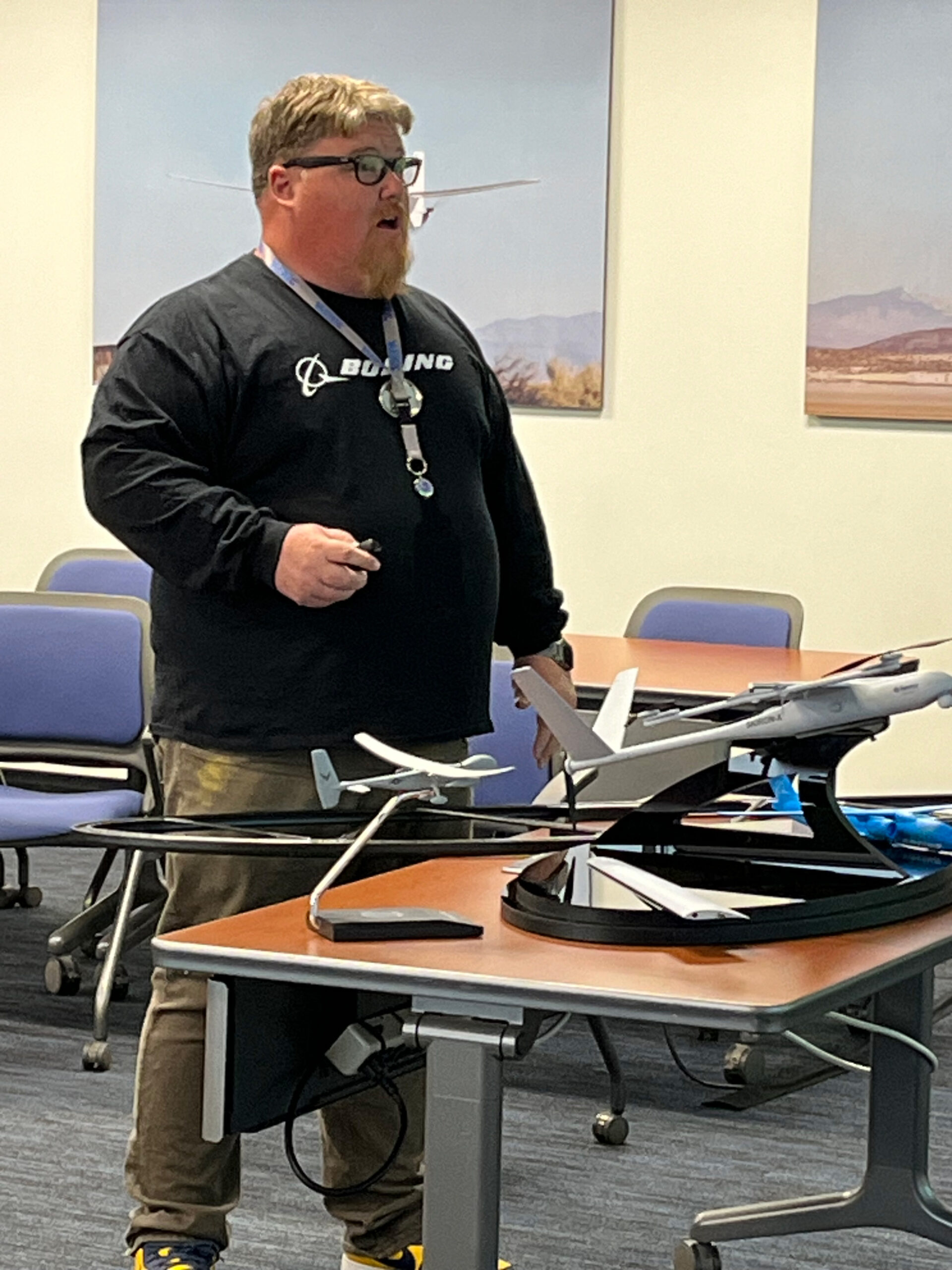

Tony Prete speaks with students visiting our Cambridge, MA office as they prepare to test their skills flying FPV quadcopters.

At Aurora Flight Sciences, a Boeing company, we are proud to support events and activities that inspire creativity and collaboration among our employees. Our sites host several employee resource groups, site engagement activities, and makerspaces, and our Manassas, Virginia headquarters even has its own employee-led multi-rotor drone racing team. This team allows both novice and seasoned drone pilots to sharpen their skills flying first-person view (FPV) quadrotors in a fun and supportive environment.

Established in 2013, the idea of the team began as a casual gathering of colleagues who enjoyed racing micro hobby shop drones. Their enthusiasm was contagious, leading them to set up makeshift racetracks complete with custom-made light-up hoops designed and built by one of the group’s members. What started as an informal after-work meetup soon evolved into a structured team, drawing in more employees to join the fun.

Employees modify their drones for increased performance during races.

Tony Prete, a structures engineer at Aurora, has been involved with the team since the very beginning.

“The drone team gives us the opportunity to apply our engineering skills in a fun environment outside of work,” said Tony. “Several members have used their engineering expertise to modify their drones to increase flight time and distance. Our racecourses take full advantage of the FPV goggles by flying drones through stairwells and on other floors of the building while the drone pilot stays put.”

Christopher Gee speaks with students about the four forces of flight.

The racing team is a unique fusion of technical skill and recreational enjoyment. Employees from a variety of disciplines across the company often find themselves applying problem-solving abilities and acquiring new skills. Members have honed soldering skills and explored innovative chassis designs to enhance drone performance.

Beyond racing, members of the team also focus on giving back to the community. In 2020, team co-founder Christopher Gee, engineering manager at Aurora, initiated efforts to support local students by introducing kids to the world of drones. Christopher put together a presentation to teach kids about the forces of flight, conduct drone demonstrations, and provide a structured environment for young enthusiasts to experience the thrill of flying.

Members of the employee-led team support a variety of outreach activities throughout the year.

“Our drone team gives kids the chance to break away from the classroom setting and experience the thrill of flight firsthand,” said Christopher. “Many of the kids we interact with have minimal to no experience with FPV drones, so they get to learn about the physics of flight then immediately put it all to the test as they fly drones through obstacles. Their enthusiasm and excitement really is contagious, and it’s a big part of the reason why we love what we do.”

So far this year, the drone team has supported four outreach events where more than 150 kids aged 12 to 17 discovered the thrill of flight. At Aurora, we are proud to advance the future of flight by inspiring the next generation to reach new heights.